Vsi Crusher Orientasi

SANDVIK CV200 RANGE VERTICAL SHAFT IMPACT

2020.4.14 TECHNICAL SPECIFICATION CV200 RANGE VSI CRUSHER - OPERATIONAL FLEXIBILITY Sandvik Stationary VSI impact crushers are designed for

Read More

Stationary VSI impact crushers, Sandvik VSI Crusher Brochure

Sandvik Stationary VSI impact crushers are designed for higher capacity and lower power consumption. The autogenous "rock on rock" crushing technique results in several major

Read More

VSI 系列立轴冲击式破碎机 VSI Series Vertical Shaft Impact ...

2018.11.15 01 产品简介Brief Introduction. VSI系列立轴冲击式破碎机是我公司最新研制成功的具有国际先进水平的新型制砂整形设备。. 多.的技术积淀,现代化加工设备的精

Read More

Modeling of Vertical Shaft Impact Crushers - Chalmers

• Introduce the vertical shaft impact crusher (VSI) and how it works. • Describe the need for innovation in the tuning of production in the aggregate sector. 1.1 Aggregates and their

Read More

Valor® Vertical Shaft Impactor (VSI) - Superior

2024.1.19 CONTACT Produce Uniform, Road-Building Material Compared to compression crushers (jaws and cones), impact crushers – like the Valor Vertical Shaft Impactor (VSI) – process a wider range of

Read More

VSI Crushers - AGGRETEK Vertical Shaft Impactors

New range of GENESIS cone crushers available in GEN250, GEN350 and GEN450 models. Aggretek's VSI Crushers (Vertical Shaft Impactor) are designed to be used in a wide

Read More

CRUSHES PERFECT PRODUCT SQUEEZES YOUR COSTS

2023.9.14 GLASS RECYCLING Sandvik VSI crushers enable minimal contamination of product. INDUSTRIAL MINERALS such as brown fused alumina, zirconia, white fused

Read More

Vertical Shaft Impactors - VSI Crushers - Stedman Machine

V-Slam™ VSI Models from Stedman are vertical shaft impactors for all your coarse-to-fine crushing needs. VSI crushers offer significant savings over higher-priced competitive

Read More

A model overview showing the parameters

2023.4.9 A model overview showing the parameters required to run the VSI crusher model at alternate speeds to predict the product PSD. The model requires a material database with fmat, E 0 min and α ...

Read More

Mathematical modeling of a vertical shaft impact crusher using

2017.9.1 Researchers from the JKMRC, on the other hand, proposed a methodology for a more direct application of the Whiten crusher model to the VSI ( Napier-Munn et al., 1996, Kojovic et al., 1998 ), which is briefly described as follows: 1. Set the parameters of the classification function (Eq. (1)) as: K 1 = 0 (all particles have a chance of being ...

Read More

fr/vsi impact rock concasseur.md at main hongyib/fr

Contribute to hongyib/fr development by creating an account on GitHub.

Read More

What Is A VSI Crusher? - konecarbide

October 31, 2023. A vertical shaft impact (VSI) crusher, also known as a sand-making machine, can efficiently turn small rocks or other materials into sand. By using a high-speed rotor with several carbide-inserted tips, a VSI crusher can accelerate the rocks and throw them against a crushing chamber’s stationary walls, thus breaking the rocks.

Read More

Mathematical modeling of a vertical shaft impact crusher using

2017.9.1 In contrast, the VSI crusher can produce more cubic particles [1–6] but with large amounts of stone powder [1–3]. Many researchers have addressed the performances of the two crushers, and they considered that the VSI crusher could be a well-established machine for high-quality crushed sand production [7–10]. In the VSI crushing process ...

Read More

Optimal energy control of a crushing process based on vertical shaft ...

2016.1.15 This paper presents an optimal control model to improve the operation energy efficiency of a vertical shaft impact (VSI) crushing process. The optimal control model takes the energy cost as the performance index to be minimized by accounting for the time-of-use tariff and process constraints such as storage capacity of the VSI crusher hopper,

Read More

Mathematical modeling of a vertical shaft impact crusher

2017.9.1 A cone crusher and a vertical shaft impact (VSI) crusher were operated in closed circuit to compare the performance of the two different crushing machines. The crushers were operated in closed ...

Read More

fr/concasseur isc 41 vsi.md at main liyingliang2022/fr

Contribute to liyingliang2022/fr development by creating an account on GitHub.

Read More

Modeling of Vertical Shaft Impact Crushers - Chalmers

• Introduce the vertical shaft impact crusher (VSI) and how it works. • Describe the need for innovation in the tuning of production in the aggregate sector. 1.1 Aggregates and their Position in Society Modern society has been built with a heavy reliance on natural materials, one of the largest sources being rock aggregates.

Read More

Modelling of output and power consumption in vertical shaft impact ...

2008.8.1 Abstract. The vertical shaft impact (VSI) crusher is a commonly-used machine in aggregate production. A comprehensive understanding of the physical phenomena that influence the power consumption and the particle output of the device are essential to enable development of protocols that minimize energy consumption during

Read More

Vertical Shaft Impactors Product Overview - Terex

2023.4.18 Impactors (VSI) crushers on the market. Robust VSI crushers are a vital tool for producing highly cubical products in small sizes and eliminating soft material. A properly configured Canica® VSI crusher is the key to minimizing wear costs and downtime – and maximizing profitability. At Canica®, we offer one of

Read More

Simulation of solids flow and energy transfer in a vertical

2013.4.1 Three crusher types are used to demonstrate these capabilities: 1. Twin roll crusher. 2. Cone crusher. 3. Vertical Shaft Impactor (VSI) These show the nature and level of fidelity that is now possible to include in particle scale crusher models including breakage of non-spherical particles and prediction of the product size distribution and ...

Read More

Simulation of solids flow and energy transfer in a vertical

2013.4.1 The VSI used in both the simulations and the physical tests is a pilot-scale machine, model Barmac 3000 Duopactor, manufactured by Metso®. The crusher essentially consists of three parts: the feed hopper (Fig. 1), the rotor and the crushing chamber (Fig. 2, Fig. 3).The feed hopper, which is typically choke-fed, is responsible for distributing the

Read More

sbm/sbm how does vsi crushers make better cubicle

You've already forked sbm 0 Code Issues Pull Requests Packages Projects Releases Wiki Activity

Read More

Sand production with VSI crushing and air ... - ScienceDirect

2015.7.1 The VSI crusher can be considered to be a well-established piece of machinery for high quality crushed sand production (Hämäläinen, 2010, Morrow, 2011, Cepuritis, 2014, Pettingel, 2008, Kaya, 2009, Robo Silicon, 2014, Sandvik Rock Processing, 2014). However, the influence of the variable parameters of the VSI crushing process (tip

Read More

Fit-for-Purpose VSI Modelling Framework for Process

2020.10.31 The worldwide shortage of natural sand has created a need for improved methods to create a replacement product. The use of vertical shaft impact (VSI) crushers is one possible solution, since VSI crushers can create particles with a good aspect ratio and smooth surfaces for use in different applications such as in construction. To evaluate the

Read More

Vertical Shaft Impact Crusher - AF Minerals Equipment

2024.1.16 The GS series crusher’s bearing seat uses a thin oil lubrication system. Its highest rotor speed is clocked at 82m/s, greatly improving the capacity of the equipment and processing efficiency. In addition, VSI and GS series crushers have been designed to minimize maintenance and improve all the adjustment operations.

Read More

How Vertical Shaft Impact Crushers Work Mellott

2023.3.13 How Vertical Shaft Impact Crushers Work. A VSI crusher works with both soft and hard materials.The material is then deflected from its original path, impacting other particles, and breaking them into smaller pieces. This process of repeated impact and reimpact results in a much finer product than traditional crushing methods, such as jaw

Read More

Investigation on the morphological and mineralogical properties of ...

2020.1.22 The VSI crusher used in this study is commonly used as one. state of crushing in aggregates generation from central and. southern areas in China. The feed rate in this study was set con-

Read More

Vertical Shaft Impactor - VSI Crushers - Impact Crushers - Pilot Crushtec

The Pilot Crushtec TwisterTrac VS350E is a fully mobile, diesel hydraulic driven, remote controlled, tracked VSI crusher. This world leading product is fully automated, features variable rotor speed and has a throughput capacity of up to 350tph. The TwisterTrac can be used on its own or easily integrated into mobile crushing plants.

Read More

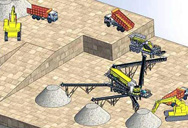

Three-stage crushing plant. Download Scientific

Figure 2 shows an example of how the crushing plant can be divided into primary, secondary, and tertiary stages. The aggregate produced in a primary crusher is classified using a screen into a 0 ...

Read More

Fine VSI Fine Equipments (India) Pvt. Ltd

The desired production volumes define the optimal size of the crusher. Rock-on-rock or anvil crushing, on the other hand, results in slightly different end products than normal tertiary and quaternary compression type crushing. NCM-FINE VSI crushers produce cubical aggregate that performs well in concrete, asphalt and base mixtures.

Read More

Crushers - All crusher types for your reduction needs - Metso

There are two basic types of jaw crushers: single toggle and double toggle. In the single toggle jaw crusher, an eccentric shaft is on the top of the crusher. Shaft rotation causes, along with the toggle plate, a compressive action. A double toggle crusher has two shafts and two toggle plates. The first shaft is a pivoting shaft on the top of ...

Read More

What Is A Vertical Shaft Impactor (VSI) Primer? - Stedman

VSI Crushing Method. The VSI is typically used after a primary or secondary crusher. This makes a VSI ideal for making sand and for making coarse and medium aggregates for concrete/asphalt production. Feed size and characteristics will affect the application of a VSI. The feed size is limited by the opening in the center of the rotor.

Read More

Energy considerations in compressive and impact crushing

2008.8.1 A cone crusher and a vertical shaft impact (VSI) crusher were operated in closed circuit to compare the performance of the two different crushing machines. The crushers were operated in closed circuit with a 9 mm final screen aperture size. A comparison of capacity, size reduction and power draw shows that the VSI crusher is

Read More

Vertical Shaft Impact Crusher - Vertical Crusher Latest Price ...

Deepa Machinery Manufacturers Private Limited. Contact Supplier. Alston Vsi Impact Crusher (VX 2000), For Stone, Capacity: 250 HP. ₹ 32 Lakh. Alston Equipments Private Limited. Contact Supplier. Impact Crusher Vsi Sand Making Machine ( VERTICAL SHAFT IMPACTOR), Model Name/Number: GVI200, Capacity: 120-150TPH. ₹ 15 Lakh.

Read More

VSI Crusher Magotteaux

As a crusher for building and road-making, the VSI is highly suitable. Simple to Run: The VSI is a solid piece of machinery. It is easy to put in place and keep up. Energy-efficient: It gives you a large volume of output while keeping its energy consumption levels down. Durable: During operation, rocks can fall into the bottom of the VSI.

Read More

What Are the Differences Between The 7 Types of Crushers?

2023.2.15 VSI crusher is generally used for the third or fourth stage crushing after the first and second crushers, which is the final link of aggregate production. It is the best machine to produce manufactured sand even better than a roll crusher. The final product of the VSI crusher is cubic in wonderful shape even can replace natural sand.

Read More

冲击式破碎机-VSI制砂机和立轴冲击破厂家价格-上海山美 ...

2024.1.10 VSI系列立轴冲击式破碎机. VSI系列立轴冲击式破碎机(VSI制砂机)是我公司研制并生产的高性能制砂设备,其性能在各种矿石细破设备中起着重要的作用。. 该系列产品集两种破碎模式于一体,是机制砂行业和石料整形领域的重要设备。. 进料粒度: ≤

Read More

(PDF) Simulation of solids flow and energy transfer in a

2013.4.1 Fig. 10 compares the collision energy spectra of rock particles ejected from the rotor when the VSI crusher is operating either with a rock bed (Fig. 2) or a ring of steel anvils (Fig. 3).

Read More

- المطاحن والأفران في مصنع الأسمنت

- محاجر جرانيت في مصر

- چگونه تولید شن و ماسه

- كسارات متنقلة نوع الزاحف

- ماكينة طحن نوى البلح

- طحن عملية لاوس للبيع

- كسارة مخروطية za

- غرامة طحن عدسة مطحنة الكوارتز

- عمان تأثير محطم الفحم للبيع

- روش نوار نقاله کمربند

- محمول مزود الفحم محطم مخروط في

- بهترین فروش سنگ شکن سنگ آهک در آفریقای جنوبی

- کارخانه سیمان مینی در بنگال غربی

- وظيفة من مطحنة الكرة في صنع الاسمنت

- بناء مصنع غسل الذهب