jaw crusher pitman armjaw crusher pitman bearing

Jaw Crusher Components Parts - 911 Metallurgist

2015.7.24 By attaching a bearing system called the pitman bearing and cap to it is possible to generate a motion whose direction is primarily

Read More

Jaw crusher pitman assembly with jaw plate, eccentric shaft and bearings

2024.1.9 Jaw crusher pitman assembly with jaw plate, eccentric shaft and bearings. A jaw crusher pitman is a key component of a jaw crusher. It is responsible for moving the

Read More

(PDF) DESIGN AND OPERATIONS CHALLENGES OF

2017.6.30 PDF A review on the design and operations challenges of a single toggle jaw crusher is presented. Strength and fracture toughness of the material to... Find, read and cite all the research you ...

Read More

Jaw Crusher

PITMAN : Pitman is fabricated from M.S plates by Mig welding process. The pitman is machined and four bearing is mounted eccentric shaft. The two bearing are fitted inside

Read More

Knowing the Basics Leads to Better Care

2023.9.11 In a typical jaw crusher, two outer bearings located on either side of the main frame support an eccentric shaft, while two inner bearings support a movable jaw.

Read More

Jaw Crusher Plants ELRUS Aggregate Equipment

6 天之前 All jaw crushers come with off the shelf spherical roller bearings for both the pitman and the frame. The pitman bearings are oil lubricated and the frame bearings are grease lubricated from a central location to

Read More

Jaw Pitman – Wear Spare Parts

A pitman of a jaw crusher comprising an upper part, which comprises an upper supporting point for supporting the pitman in the body of the jaw crusher, and a lower part

Read More

Jaw Pitman - High-Quality Cast Steel for Jaw Crushers

2023.12.28 We offer a wide range of replacement jaw pitman for jaw crushers, expertly machined to specification for fast, easy installation and good fit. Choose our jaw

Read More

Jaw Crusher Pitman Shanghai GDOO Mining

Jaw Crusher Pitman. The pitman is the main moving part in a jaw crusher, which forms the moving side of the jaw. A jaw crusher pitman has two supporting points for supporting it in the body of the jaw crusher, the

Read More

The Design of Rolling Bearing Mountings - Schaeffler

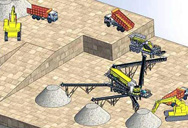

2019.5.24 92 Double toggle jaw crusher Double toggle jaw crushers have a large mouth open-ing. They are used, for example, as primary crushers to prepare ballast for road building. The coarse crushing is followed by further crushing operations until an ag-gregate of the size and shape required, e.g. gravel or grit, is obtained. Operating data

Read More

US20130043335A1 - Pitman of a jaw crusher, jaw crusher, crushing plant ...

2011.8.18 A pitman of a jaw crusher comprising an upper part, which comprises an upper supporting point for supporting the pitman in the body of the jaw crusher, and a lower part comprising a lower supporting point for supporting the pitman in the body of the jaw crusher through a toggle plate. The lower part of the pitman comprises sidewalls and

Read More

Jaw Crusher Pitman Genuine Alternative Spare

3 天之前 Description. The pitman is the main moving part in a jaw crusher, which forms the moving side of the jaw. A jaw crusher pitman has two supporting points for supporting it in the body of the jaw crusher, the

Read More

Jaw Crusher Plants ELRUS Aggregate Equipment

6 天之前 ELRUS jaws crushers are available in sizes: 1536, 2036, 2236, 2442, 2054, 3042, and 3054. ELRUS Jaws Feature: Oversize bearings and shafts. Central point lubrication. Oil lube inner bearings, grease outer bearings. Bolt on Pitman lip. Hydraulic toggle block adjustment. Full Hydraulic toggle - optional.

Read More

Nordberg® C Series™ jaw crushers - Metso

The core of Nordberg® C Series™ jaw crusher is a pinned and bolted, non-welded frame construction that provides excellent fatigue strength. All the frame components are casted using an alloy developed in-house especially for jaw crushers. In addition to solid casting, the crushers’ frame has a cellular, so called honeycomb structure that ...

Read More

Industrial Solutions Jaw crushers - ThyssenKrupp

2022.11.21 The single-toggle jaw crusher with the largest antifriction bearings and highest flywheel energy 1) ... bearing Back wall Jaw adjustment Toggle plate Pitman Clamping bar Shim plate Cheek plate Front wall Side wall Fixed jaw ... trolled by a pitman that moves up and down under the influence of an eccentric shaft,

Read More

What Is A Jaw Crusher - MEKA

/ JAW CRUSHER TYPES. There are two main groups of jaw crushers, categorized according to their jaw movement mechanism. - Single-toggle jaw crushers - Double-toggle jaw crushers. In single-toggle jaw crushers, the movable jaw is supported by the bearing on an eccentric shaft driven by the pitman to which it is attached. The pitman is supported ...

Read More

Manual C145 Jaw PDF Safety Manufactured Goods - Scribd

2023.6.19 1 Front frame 12 Moving jaw, lower 2 Upper wedge 13 Frame bolt 3 Filling wedge 14 Fixed wedge 4 Jaw bolt 15 Pitman eye protection plate 5 Disc spring package 16 Flywheel 6 Cheek plate, upper 17 Eccentric shaft 7 Fixed jaw, upper 18 Pitman bearing 8 Moving jaw, upper 19 Pitman 9 Center wedges 20 Frame connecting rods 10 Cheek

Read More

Jaw crusher parts - Metso

Jaw crusher wear parts are designed for processing all rock types in surface and underground operations. Our offering consists of jaw plates such as different one-piece jaws and two-piece jaws as well as cheek plates. Due to the wide range of applications and feed materials, our jaws are available in several different designs and alloys.

Read More

The Most Practical Jaw Crusher Repair and

2023.2.15 Common problems during inspection and repair of jaw crusher How to tell when pitman bearings are bad on a jaw crusher? 1 The internal contamination of the bearing is too high, which is mainly

Read More

Nordberg C Series jaw crushers - International Crusher

2018.1.17 known traditional jaw crusher range that is designed for stationary as well as mobile applications (C80, C100, C3054, C120, C125, C140, C150, C160, C200). The second range ... The pitman, crusher frames, and bearing housings . are made of high-quality cast steel. 6 7 The right cavity design HIGH PERFORMANCE.

Read More

Knowing the Basics Leads to Better Care - timken

In a typical jaw crusher, two outer bearings located on either side of the main frame support an eccentric shaft, while two inner bearings support a movable jaw. These are commonly known as “Pitman” bearings. The reciprocating motion of the shaft moves the Pitman against a second, stationary jaw.

Read More

Jaw Crushers - Armstrong Equipment

JC2236 Jaw Crusher: 24,903 (11,296) 22 x 36 (560 x 915) 90-125 (67-93) JC2248 Jaw Crusher: 43,094 (19,547) 22 x 48 (560 x 1220) 125-175 (93-130) JC3660 Jaw Crusher: ... Hydraulic assist bearing removal for both pitman and side bearings (JC3660 and JC5460) Hydraulic/shim toggle seat adjustment (discharge opening) One smooth and one

Read More

Below the surface: Setting up an underground primary jaw crusher

2014.4.1 The heaviest part of a Metso C200 jaw crusher for maintenance is the pitman assembly, which weighs about 40 tonnes and requires 5m of vertical space plus clearances for lifting. ... Then lay the pitman from the jaw crusher on its side to work on bearings or place the gyratory main shaft upright. When the hole is not in use, it must be

Read More

Engineered for the toughest feed materials Nordberg®

2020.7.24 example, pitman eye protection protects the bearings and the pitman casting from impacts caused by really coarse feed, and it is also effortless to change. Even the main frame components are changeable thanks to the pinned and bolted design, prolonging the potential lifetime of the jaw crusher. Nordberg C Series jaw crushers are

Read More

AGGREGATE AND MINING BEARINGS AVAILABLE FOR

2017.11.1 Contact Messinger to learn how our core skills and experience can deliver unparalleled technical support, expert field service, and timely delivery to help you maintain superior machine performance. For application assistance or to get a quote, visit our web site. 10385 Drummond Road, Philadelphia, PA 19154 Ph: 215-739-6880 Fx: 215-824

Read More

Arizona Construction Equipment, Inc. WWW.AZCE.COM

2019.10.1 Removable pitman/bearing assembly for maintenance ease Hydraulic shim adjustment Heavy duty, cast steel pitman with machined barrel Machined pitman face for full swing jaw die ... Jaw Crusher Capacity in Tons 30 x 42 100-125 125-150 32 x 42 36 x 48 Closed Side 10 x 30 Setting 3/4 10 -15 19mm 15 -25 25.4mm 1-1/2 " 25 -35 38.1mm 40

Read More

Proven reliability and performance Nordberg® C

2023.6.2 long-lasting wear items. For example, pitman eye protection protects the bearings and the pitman casting from impacts caused by really coarse feed, and it is also effortless to change. Even the main frame components are changeable thanks to the pinned and bolted design, prolonging the potential lifetime of the jaw crusher. Long-term investment

Read More

(PDF) Operation Maintenance Vanguard Series

It is the owner/operator's always be covered by specific responsibility to insure rules. 8. Clear area of people everyone operating the before starting the equipment is familiar with safe 1. Read and understand the conveyor. operation and maintenance of Operator's Manual before the jaw crusher.

Read More

“Computer Aided Design of Jaw crusher” - National

2010.5.14 1.4 Crusher Size and Power rating: The size of a jaw crusher is usually expressed as gape x width. The common crusher types, sizes and their performance is summarized in Table 1.1.Currently, the dimension of the. largest Blake-type jaw crusher in use is 1600 mm x 2514 mm with motor ratings of 250-300. kW.

Read More

Gyratory VS Jaw Crushers: Advantages

2016.2.28 Large receiving opening per dollar of investment. Shape of receiving opening favourable for blocky feed. This, plus point 1, give the jaw a definite advantage over the gyratory, except in the very large sizes, for

Read More

Jaw Crusher Parts Aftermarket Wear and Spare Parts GTEK

3 天之前 The the jaw plates and the cheek plates are the most common replacement parts on a jaw crusher. GTEK™ can produce jaw plates with different tooth shapes and materials according to the your application. Our cheek plates are start from 13% Manganese with 2% chrome iron (Mn13Cr2). And our standard crusher jaws range from Mn13Cr2, Mn18Cr2

Read More

(PDF) Optimum design and analysis of (the) swinging jaw

2010.4.30 Fig.4.5 swinging lever or pitman of the single toggle jaw crusher 52 Fig.4.6 assembled structure of swinging jaw plate with pitman 52 Fig.4.7 Finite Element Analysis Process in CATIA 54

Read More

MS Series Jaw Crusher Crushing Equipment Minyu Machinery Corp.

2023.8.7 Large deep crushing chamber with sharp crushing angle, to achieve a very high crushing ratio. The MS-Model with bigger feed opening and longer pitman arm is especially suitable for primary crushing. Recommended for big lumps large quantities, for primary crushing of limestone, river stone, tough ores, and concrete recycling.

Read More

PDQ Replacement Parts Guide - KPI-JCI

2020.2.20 1036 CEDARAPIDS® JAW CRUSHER FINAL ASSEMBLY SHAFT, PITMAN BEARING PART NO. DESCRIPTION PART NO. DESCRIPTION A00507SS Key Plate A00696SS Collar, Pitman A00234 Washer, Flat A07031066 Bearing, Pitman A01036WDU04A Toggle Seat A0103600115 Flinger A00509SS Wedge, Moveable Jaw

Read More

Nordberg® C Series™ jaw crushers Proven reliability and

2021.7.16 by long-lasting wear items. For example, pitman eye protection protects the bearings and the pitman casting from impacts caused by really coarse feed, and it is also effortless to change. Even the main frame components are changeable thanks to the pinned and bolted design, prolonging the potential lifetime of the jaw crusher. Long-term investment

Read More

Jaw Crusher Explained - saVRee

For example, a 32 x 54 sized jaw crusher will measure 32 inches from the movable to stationary jaw (when measured at the top i.e. the opening), and each jaw will have a 54-inch width. If a jaw crusher is rated by jaw plate size, a suitable rating maybe 600 x 400, which indicates a 600 mm by 400 mm jaw plate dimension.

Read More

Small Jaw Crushers - 911 Metallurgist

2016.6.1 Sizing a Small Jaw Crusher (Anti-Friction Bearings) Small Jaw Crushers (or the Blake Type) are an exceedingly strong, serviceable machine, widely used in milling operations, also for general crushing equipment and work. It is especially adapted to handling blocky ore requiring large jaw openings 3″, 4″, or 5″ in size.

Read More

Dodge Crusher - 911 Metallurgist

2016.2.23 Dodge Crusher. A sectional view of the Dodge jaw crusher here below. The mechanism of this machine is so simple that it is hardly necessary to enlarge upon what can be gained from an examination of the cut. Dodge-type crusher parts: (1) Frame, 12) Main bearing cop, (3) Oil well cover, (4) Oil well cover spring, (5) Swing jaw shaft box, (6 ...

Read More

- الجير الدقيق طاحونة مفتوحة إلى ما هي المعدات

- محطة كسارة svedala في نوفمبر

- سنگ شکن ضربه گیریل برای فروش

- يمه يمه ماشا المطحنة mp

- دستگاه خرد کن دستگاه سنگ شکن ماشین

- عملية الطحن معالجة

- گزارش پروژه کارخانه خرد کردن شن

- إنتاج الألومينا من البوكسيت الباكستاني

- صينية الصنع طاحونة كهربائية

- استخراج از معادن زغال سنگ satui اندونزی

- کارخانه سنگ شکن برای زغال سنگ

- مصنع كسارة فريدة من نوعها

- جامع الغبار مطحنة الفحم

- الكوارتز مصنع سحق من أوروبا

- الكرة مطحنة من Falsfair